Filament Matters

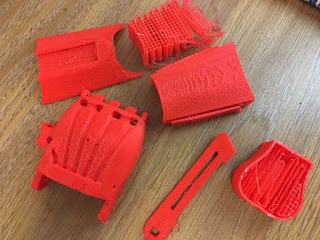

Today, we came back we came back to a 3D print that was strange. It was very easy to take apart. Could the problem have been slicing the hand? Could it have been the filament itself?

We scraped out the glue and re-leveled the bed. We also replaced the filament to white PLA. The temperature is set to 210 and the build plate, 65 degrees. We are going to print a calibration cube to see what the actual error is.

We dealt with our first clog today! We had to heat it to 215 degrees and push the material out. We did so successfully, but in the process we noticed that the new filament we had was very brittle, so it cracked easily. That is why the print would not go well.

So, we had a road-trip! We went to buy new filament nearby. It was 3mm, blue PLA. We tried to reprint the calibration cube without even adjusting the settings and the cube came out perfectly! Elda even stood on it to test its strength and it remained untouched! That goes to show how much good filament has to do with the quality of the print, especially for important ones like prosthetic hands.

True.

Comments

Post a Comment